WaveWise

Role

Electrical & Computer Engineer

Tools & Technology

KiCAD, Arduino IDE, Reflow Oven, JLCPCB

Skills

PCBA Design, Arduino Coding, Soldering, Electrical Debugging

Time

August 2023 - December 2023

WaveWise

Electrical & Computer Engineer

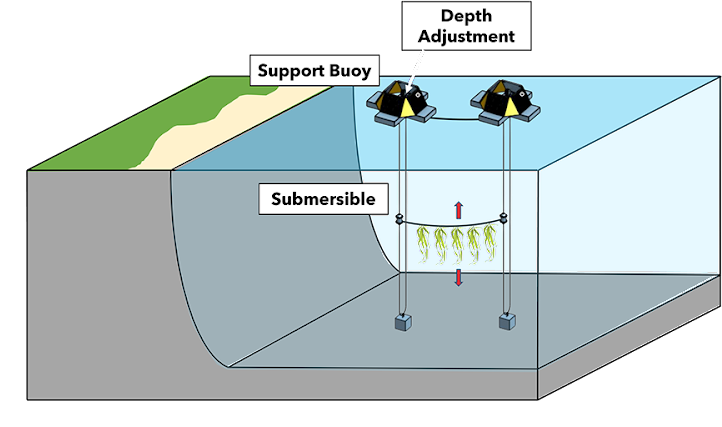

Maine's sugar kelp production faces challenges such as location restrictions

and limited monitoring capabilities. Our client WaveWise approached Generate,

Northeastern's product development club, to create a prototype capable of

dynamic depth adjustment for optimal kelp growth. Our team of 11 talented

individuals delved into researching, ideating, designing, and testing a system

that incorporated a winch system with stepper motor powered depth control.

As an Electrical & Computer Engineer on the team, my primary focus was on

power systems, software architecture, and the design and bringup of the Buoy

PCBA. I collaborated closely with the five other EECEs and our mechanical

engineering counterparts, contributing to the incredible product we were able

to showcase at the end. It was a fulfilling experience working on WaveWise,

navigating the challenges, and contributing to a multifaceted project that

blended innovation with sustainability.

Initial Research

Power Management: Storage, Generation, and Control

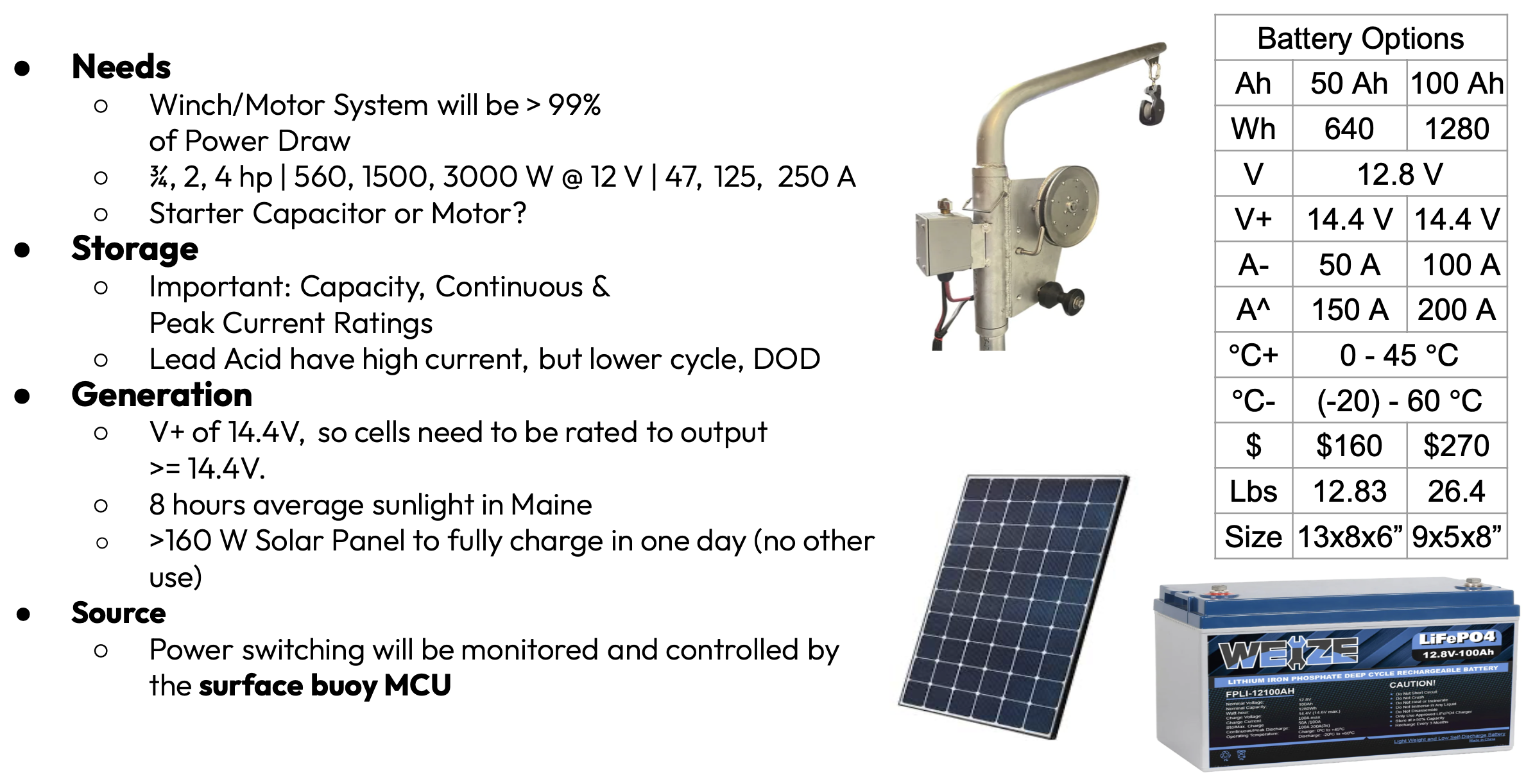

When initially tasked with overseeing the power system, I used an existing system—the

crab pot puller—as a baseline for power draw requirements. I operated under this

power assumption while our mechanical engineering team calculated our specific motor

wattage needs. Below are some of the major considerations I took into account when

designing and selecting components for the system:

- Temperature

- Continuous/Peak Discharge

- Capacity

- Weight

- Lifetime Expectancy (cycle count, ratings)

- Environment

Most of the crab pot pullers I found were in the range of 3/4 to 4 hp, equating to

approximately 500 to 3000 W. At the initially planned 12V for our design, this meant a

current draw of 125 A for a 2hp equivalent system. I then made the decision to run our

system at 48V. With these considerations in mind, I opted for LifePo4 batteries due to

their high power density, lower cost compared to Li-ion, and favorable temperature,

cycle count, and discharge characteristics.

Final Power Architecture

Hard Numbers: Calculations in and Multiple Revisions Later

After receiving updated power value calculations from the mechanical team, significant

changes were made to the power design. With motor power requirements adjusted to 180W,

a 288W motor was selected for its holding torque of 8.5nM, providing a Factor of Safety

(FOS) of approximately 1.5x at 48V. The stepper motor was chosen for its 'locking'

capabilities and measurable movement based on steps. At 48V, the stepper motor would

draw a max continuous 6A, much more reasonable than the current we were looking at

originally. We also chose a Pololu motor controller that offered feedback data,

including a stall line, and the flexibility to adjust micro-stepping for future torque,

energy, and vibration optimization.

I chose a 48V, 10AH LiFePO4 battery pack with a built-in 20A BMS that would provide ample

power for peak draw requirements, supporting over an hour and a half of continuous use.

Realistically, the motor would not be running at full power continuously, and rather only

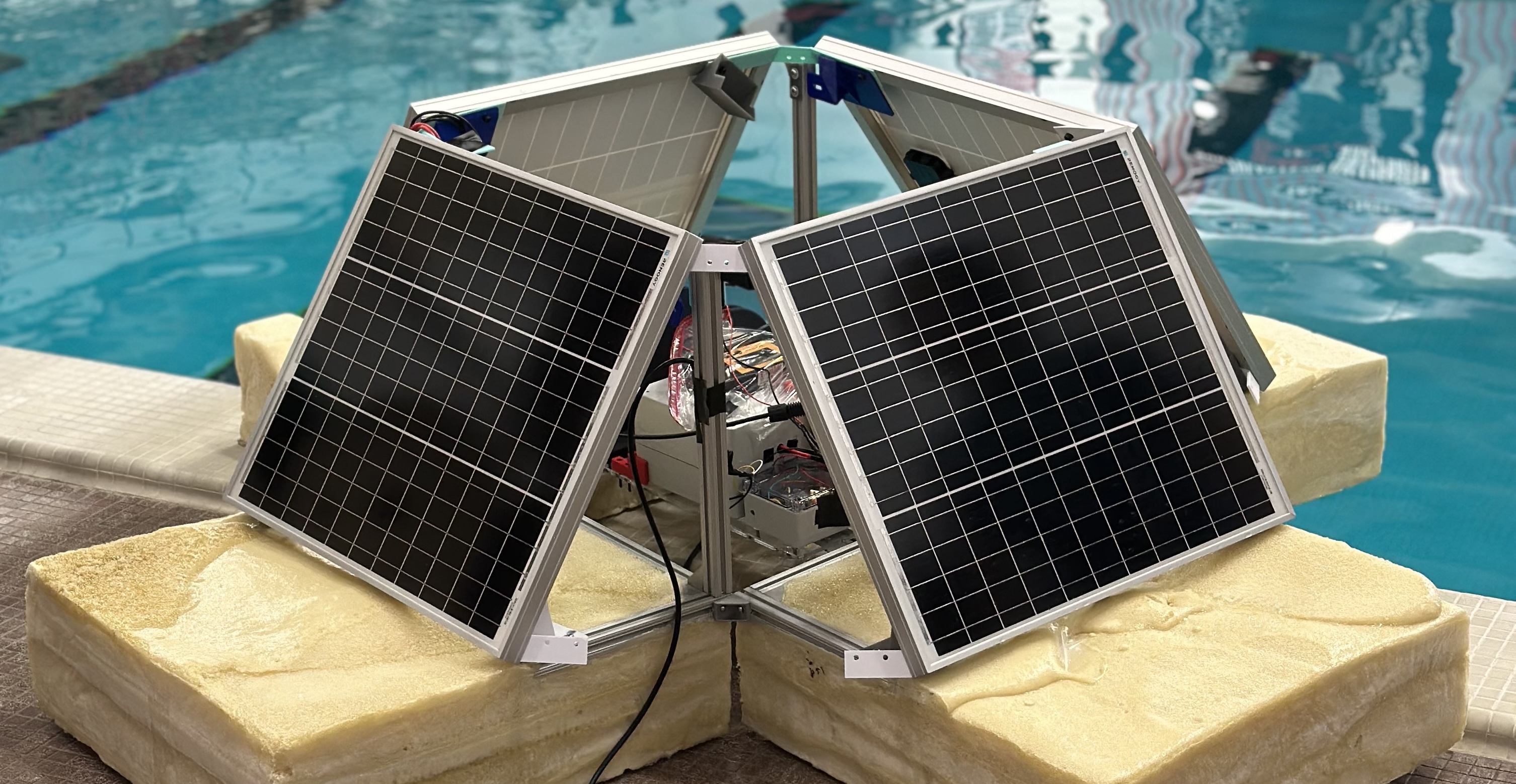

have this hour and a half of use over 2-3 days at the worst. Complementing the battery,

four 12V solar panels in series, each rated for a maximum of approximately 4 Amps, were

introduced to recharge the battery ensuring that it never discharge. This solar setup could

almost fully sustain full motor power and charge the battery from 0-80% in two hours. To

streamline the charging process and address time constraints, a dedicated charge controller

was acquired instead of designing a custom switching circuit. The controller chosen ensures

the battery is charged at the required 55V, accommodating the solar panels' peak supply of

74.4V under optimal conditions. At this point, the high voltage power architecture was

complete, and the purchases had been made.

Software Architecture

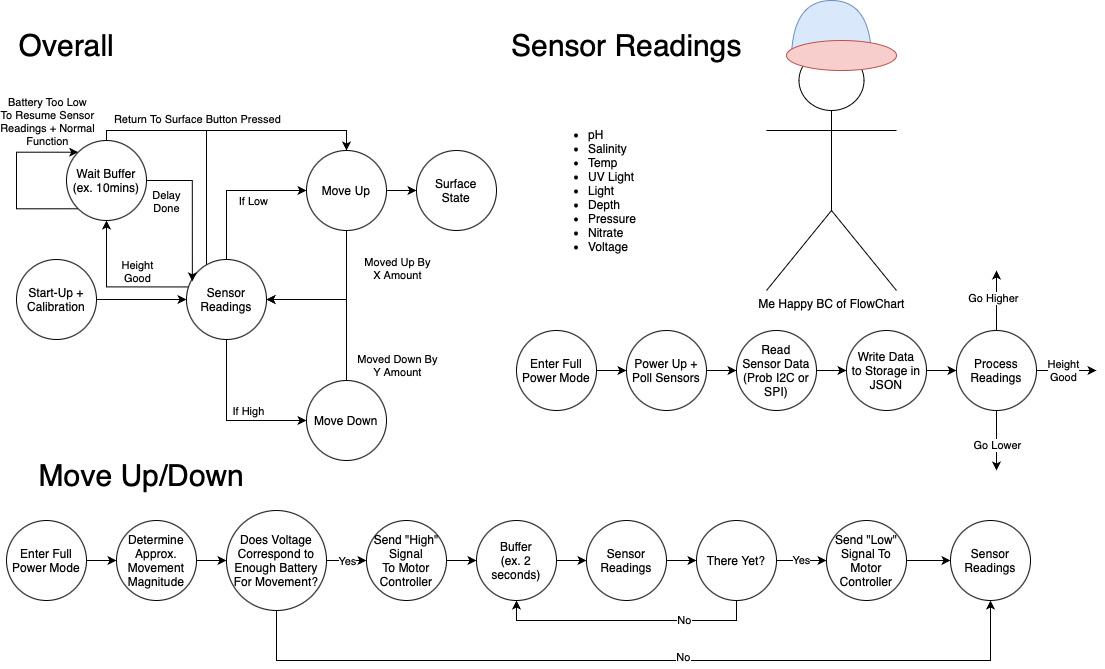

The Flowchart: States, Sensors, & Actions

In the realm of software architecture for the WaveWise project, the focus was on

efficient and responsive handling of sensor data and movement control. I mean just

take a look at that awesome flowchart I made below! The software design was divided

into three main segments: Overall, Sensor Readings, and Movement.

Overall:

This incorporates cycles of sleep mode to conserve battery, lasting 10 minutes each,

and periodic checks of the sensors to assess the necessity of movement before

transitioning back to a low-power state.

Sensor Readings:

In this phase, the system enters a full-power mode where all sensors—measuring pH,

salinity, temperature, UV light, depth/pressure, and nitrate—are activated and polled.

The information gathered from the sensors is read through either the I2C or SPI lines.

The sensor reading process also involves the storage of data in JSON format on an SD

card for further data analysis as per the clients request. This phase was a crucial

bridge between data collection and subsequent decision-making.

Well, the client requested nitrate data, but its sensor would have single-handedly

eaten up our entire budget.

Movement:

When deemed necessary based on sensor readings, the system transitions into the

movement mode. This phase orchestrates the required movements until sensor readings

reach satisfactory levels. An important condition for movement is the

verification of a sufficiently high battery voltage ~(>15%) charge to guarantee

uninterrupted system functionality.

Key Decisions

Ups, Downs, & Inbetweens

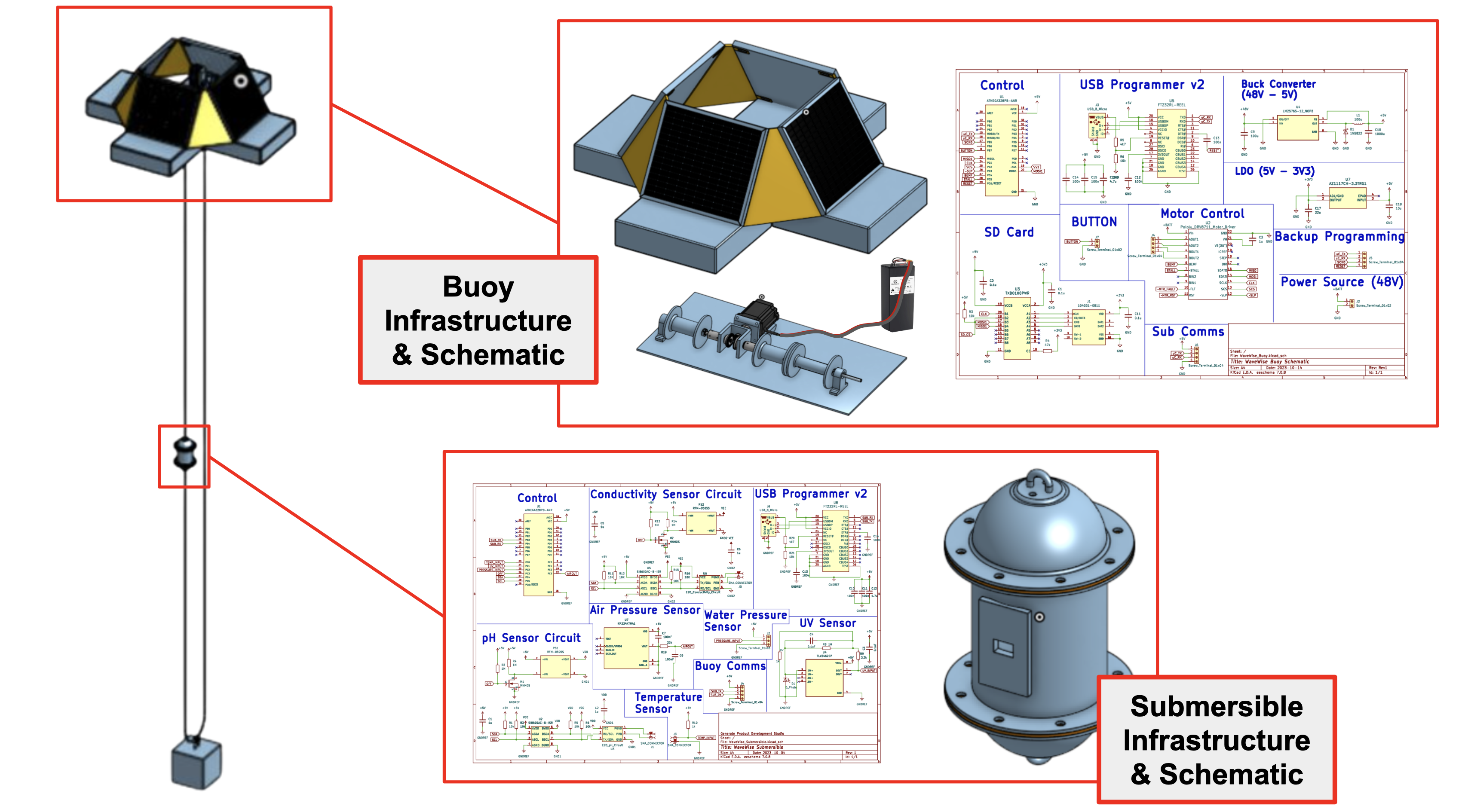

A major decision we made was to go custom and design PCBs, ditching the tried and true

Arduino and Raspberry Pi. This was partly for the challenge, but more importantly,

it let us tailor the boards to snugly fit into our mechanical setup. Plus, we foresaw

weird connectors for certain sensors, so custom PCBs with the right connectors it

was – no messy soldering directly onto Arduino’s with a birds nest of wires (almost).

When it came to programming the boards, we ended up using the Arduino IDE. We were

able to do this by choosing the ATMega328PB as our MCU and using a FTDI chip for

programming. You'll hear about the mess of a time we had boot loading these MCUs

later on. The Arduino IDE came in handy with its quick uploads and plethora of built

in and add on libraries.

One of the biggest decisions we made was creating two PCBs. One in the floating

buoy, taking care of logic control, and the other down in the submersible, playing

host to all the sensors. They would communicate over UART, with the submersible

sending data up to the buoy for analysis and saving on an SD card. We decided to

run both ATMegas at 5V instead of 3.3V. The main reasons for this was that all

sensors could run at 5V whereas only a few would run and output data at 3.3V.

The 5V over UART would also be more stable according to our research.